What is the difference between Ceiling Coving and Cornice?

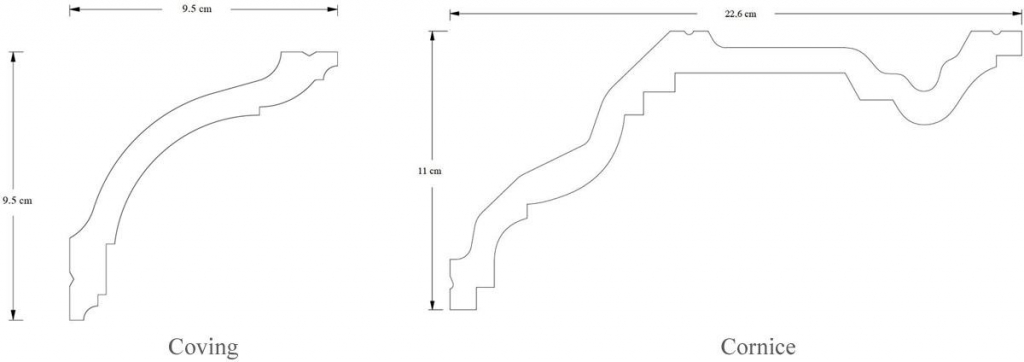

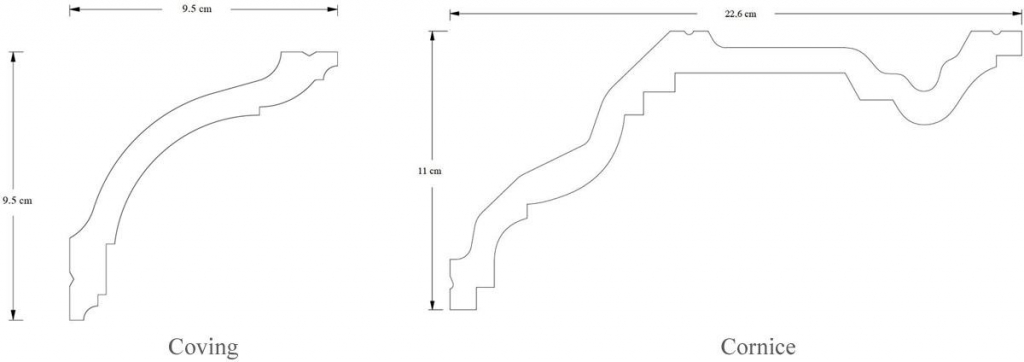

Quite frankly it is pretty much the same thing. But whilst not an absolute rule, coving is the term that is often applied to a moulding that is generally uniform in profile, projecting across the ceiling roughly the same distance as the drop down the wall (so it could be 10cm x 10cm for example). Generally speaking, it is simpler in design and is typically (though not always) formed around the traditional quarter-circle ‘C’ profile.

Coving profiles tend to come in different sizes, the most common of which is the 5” (127 mm) cove. This measurement often causes confusion – it refers to a straight line drawn across the diagonal from wall to ceiling (not the height or projection of the coving, which – for the 127mm cove – is actually 80 mm x 80 mm).

Most house builders in the post-war period installed this plain cove because it was simple and effective – and very cheap to make. It is still probably the most common coving profile in Britain.

Cornice on the other hand often tends to be much more ornate and is less uniform dimensionally (though it could potentially still have the same projection and drop). So a piece could be 150mm across the ceiling but only 100mm down the wall (or vice versa). The shape of a cornice can also be very complex indeed, with different curves and flats in the design. There have been numerous styles and patterns reflecting the changing architectural fashions of the time.

Side profile diagram of example Coving and Cornice profiles:

Traditional plaster decorative coving and cornice

Plaster (often using lime and hessian backing) is traditionally the manufacturing material. However, the inherent problem with plaster is that it is both extremely heavy and fragile. Aside from the cost and risk of damage when transporting, problems would occur when hanging this weight from the ceiling. Any subsequent movement in the wall or ceiling often meant unsightly cracks would appear, and – at worse – sections falling off. The 1970’s ‘solution’ was polystyrene which, whilst cheap and easy to install, was visually poor and proved unpopular.

Modern coving materials

Technology has improved dramatically since then and the industry-standard material is now hardened polyurethane. This has the visual beauty of plaster coving but without the inherent disadvantages. It is best described as being like ‘light wood’. A nice clean, sharp edge is achieved by cutting with a standard medium tooth crosscut saw or alternatively an electric mitre or ‘chop’ saw with an 80-tooth blade.

Joins can be made virtually invisible by using a small amount of Decofix Ultra joint adhesive and FL300 filling compound, followed by a final coat of finishing paint.

Installation benefits of hardened polyurethane mouldings

The lightweight nature of this material means that adhesive is all that is required in order to install – no screws are necessary. An undercoat/primer is also already applied for the coving to be painted with a final finish coat. And the final look? The same as with plaster cornice but without the anguish and frustration.

If you need any further advice we are very happy to discuss your requirements with you – please call us on 020 8660 2854

You can also see our Coving Installation “how to” videos on our YouTube channel.

“L” = Length/span

“H” = max Height/Drop (i.e. down the wall from the ceiling) in cm

“P” = max Projection (i.e. the measurement across the ceiling from the wall) in cm